What is Cold Foil Printing?

In the world of printing and packaging, cold foil printing has emerged as an innovative and cost-effective technique that elevates design to a new level of sophistication. From high-end product labels to luxurious packaging, cold foil printing provides a stunning finish that adds a touch of glamour and durability to any material. But what exactly is cold foil printing, and why are so many industries turning to it for their branding and marketing needs? Let’s take a closer look at this versatile process and the many benefits it offers.

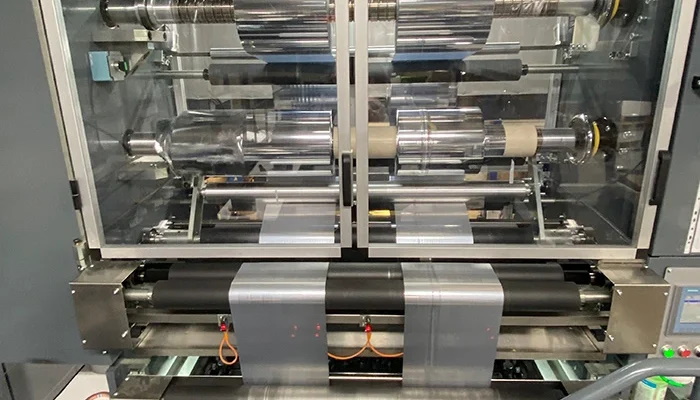

Unlike traditional hot foil stamping, which relies on heat, cold foil printing is achieved through a two-step process that doesn’t involve high temperatures. First, a special adhesive is applied to the areas where the foil will appear. Once the adhesive is in place, a layer of foil—often in gold, silver, or other metallic hues—is pressed onto the surface. This process is precise and efficient, creating striking visual effects without the need for heat, making it ideal for a wide range of applications.

One of the key advantages of cold foil printing is its versatility. It can be applied to a wide variety of materials such as cardboard, paper, and labels, which opens up endless creative possibilities for designers. Whether you’re working on product packaging, marketing materials, or even custom stationery, cold foil printing adapts beautifully, allowing industries like cosmetics, food and beverage, and pharmaceuticals to create eye-catching, premium designs with ease.

When it comes to customisation, cold foil printing truly shines. It’s highly flexible in terms of design, making it possible to apply foil to specific images or text or even cover an entire sheet with a shimmering metallic layer. The technique allows designers to explore intricate patterns, fine details, and larger decorative areas without losing quality or impact. This makes it a popular choice for brands looking to make a bold statement with their packaging and promotional materials.

One of the most significant advantages of cold foil printing is its cost-effectiveness. Compared to traditional hot foil stamping, cold foil printing offers a more affordable way to achieve a high-end look. Because the process is quicker and doesn’t require heated dies, it helps reduce production costs, making it an attractive option for companies seeking premium designs without breaking the bank. This is especially beneficial for larger print runs where cold foil printing can provide consistent, impressive results at a fraction of the cost.

In addition to its aesthetic appeal, cold foil printing also adds a practical layer of protection to printed materials. The foil acts as a barrier against environmental factors such as moisture, light, and abrasion, making it ideal for packaging that needs to withstand wear and tear. This durability is particularly useful in industries where packaging integrity is crucial, ensuring that products remain protected while still looking visually appealing on the shelf.

Perhaps the most compelling reason to consider cold foil printing is its ability to create striking, eye-catching effects. Research has shown that packaging adorned with foil rates over 80% higher in consumer interest than those without, underscoring the power of this technique to enhance branding and marketing efforts. Whether used sparingly to highlight key details or applied generously for a luxurious finish, cold foil printing commands attention and helps products stand out in crowded markets.

Here at Philtone we find that cold foil printing is a game-changer for businesses looking to elevate their designs and packaging. With its versatile application, cost-effective production, enhanced durability, and undeniable visual impact, it’s no wonder that more and more brands are embracing this technique. Whether you’re looking to add a touch of luxury to your product or make your marketing materials stand out, cold foil printing offers a simple yet powerful solution for achieving dazzling results.

Company Profile

MCH HUBS

RECENT ARTICLES